TDS water well drilling rig is a lightweight, efficient, versatile drilling hole equipment, which borehole drilling machine is mainly applied in drilling wells, irrigation wells, geothermal wells and air holes for other purposes, especially for mountain and rock formation water engineering. The water well drilling rig machine can work on different formations, well drilling diameter up to 245mm. The drill machine adopts new hydraulic technology, supporting high torque hydraulic motor rotation and big bore drill hydraulic propulsion, branded multi-cylinder engine-powered two-stage air filter and the intake air compressor designed for hydraulic systems, extend the life of diesel engines. Unique pump design to facilitate maintenance, reduce maintenance costs. Centralized hydraulic control console, easy to operate. Operating steps of the drilling rig. 1. Start the diesel engine. Allow the diesel engine to run for 10~20 minutes before further operation. 2. Push the traveling manipulator valve to move the drilling rig to the drilling position; push each handle on the cylinder manipulator valve to adjust the slide frame to the block position and then fix it. Fine tune the 4 outrigger cylinders to ensure the drill pipe is vertical and downward. 3. Open the ball valve switch on the air inlet line and the impact manipulator valve to feed air to the impactor, and push the rotary manipulator valve at the same time to make the rotary drive the drill pipe and impactor to turn positively, then slowly push the advance manipulator valve to make the needle gradually close to the ground, and the impactor start working after contacting the ground. 4. It is strictly forbidden to use the impactor for soil drilling.

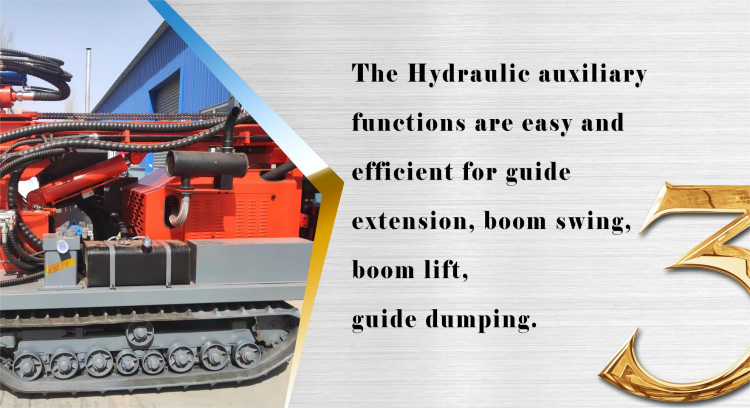

TDS water well drilling rig is a lightweight, efficient, versatile drilling hole equipment, which borehole drilling machine is mainly applied in drilling wells, irrigation wells, geothermal wells and air holes for other purposes, especially for mountain and rock formation water engineering. The water well drilling rig machine can work on different formations, well drilling diameter up to 245mm. The drill machine adopts new hydraulic technology, supporting high torque hydraulic motor rotation and big bore drill hydraulic propulsion, branded multi-cylinder engine-powered two-stage air filter and the intake air compressor designed for hydraulic systems, extend the life of diesel engines. Unique pump design to facilitate maintenance, reduce maintenance costs. Centralized hydraulic control console, easy to operate.

TDS water well drilling rig is a lightweight, efficient, versatile drilling hole equipment, which borehole drilling machine is mainly applied in drilling wells, irrigation wells, geothermal wells and air holes for other purposes, especially for mountain and rock formation water engineering. The water well drilling rig machine can work on different formations, well drilling diameter up to 245mm. The drill machine adopts new hydraulic technology, supporting high torque hydraulic motor rotation and big bore drill hydraulic propulsion, branded multi-cylinder engine-powered two-stage air filter and the intake air compressor designed for hydraulic systems, extend the life of diesel engines. Unique pump design to facilitate maintenance, reduce maintenance costs. Centralized hydraulic control console, easy to operate.

Geological exploration Water well drilling rig

Geological exploration Water well drilling rig